What Is a High Current PCB and Why Does It Require Specialized Receptacles?

So, here’s the thing about high-current PCBs: A high-current PCB isn’t your everyday circuit board. These things are designed to handle serious power, think 10, 20, sometimes even 50+ amps. That’s not “LED-blinking-on-a-hobby-board” territory. It’s automotive, EV systems, motor controls, charging stations, and heavy-duty industrial electronics.

In those environments, your components can’t just work.

They have to withstand stress.

And keep working.

Defining high current PCBs (and why they’re different)

At a basic level, high current PCBs are just circuit boards designed to carry a large electrical load, much higher than typical signal boards. Think 10 amps, 20 amps, sometimes even 50+, depending on the application.

That’s not your everyday smartphone stuff.

These are the circuit board sockets fueling electric vehicle systems, charging stations, robotics, motor drives, and control panels in manufacturing lines. If it drives a machine or maintains the flow of energy in a high-stakes setting, chances are there’s a high-current PCB behind it.

But here’s the challenge: when current goes up, heat does too.

And that’s where things get tricky.

Why standard connectors just won’t work

Ever seen a cheap connector fail?

It’s not pretty.

Plastic warps. Pins corrode. Connections loosen over time. Worst case? Complete failure. And when you’re working with high currents, that’s not just inconvenient—it’s dangerous. Overheating, arcing, or even fire can result from poorly rated socket connector pins or general-purpose receptacle connectors.

Most traditional pin sockets for PCBs just aren’t designed with that kind of load in mind. The metal thickness is too thin, the contact pressure isn’t right, or the materials can’t handle the long-term thermal stress.

So if you’re pushing a product into production that deals with serious amps, your pin receptacle can’t be an afterthought.

It needs to be engineered with intention.

So, what’s the fix?

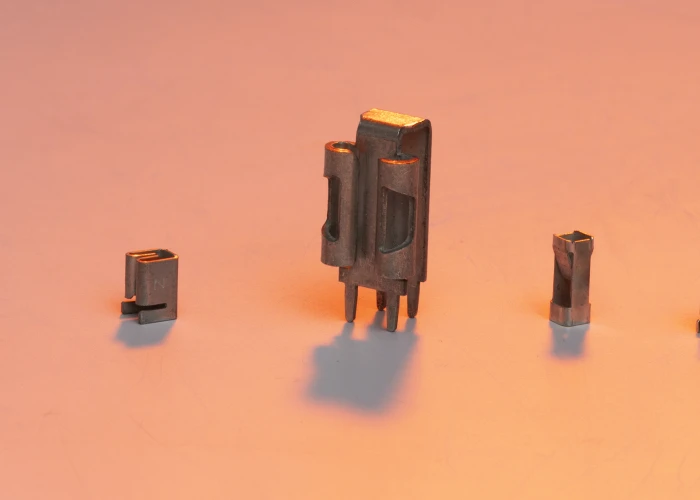

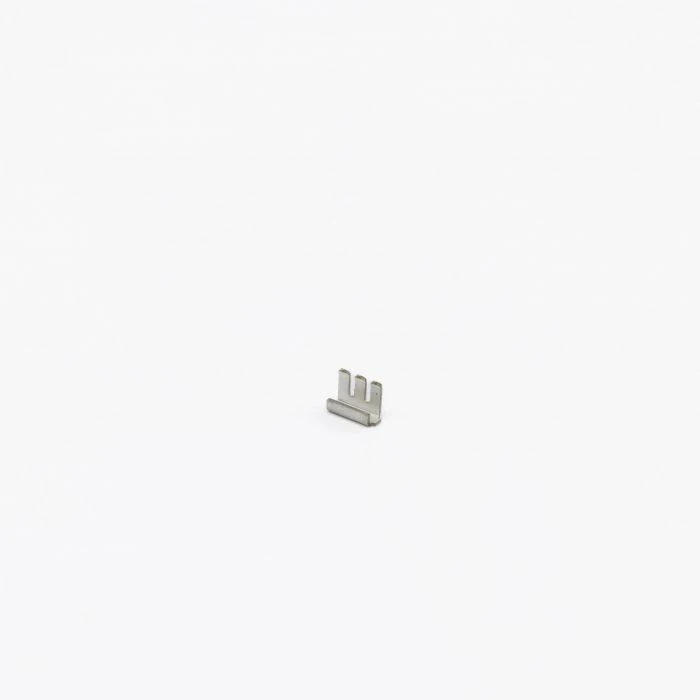

Enter Zierick’s Product 1297. This isn’t your average pc circuit board socket. It’s a high-current PCB receptacle designed specifically for demanding electrical environments, ones where performance isn’t optional.

Let’s break it down.

- Rated to 15 Amps continuous

That’s a lot of juice. And it’s sustained, not just peak. The contact system in this socket connector pin is built to handle that kind of load without heating up or degrading over time. - Robust materials and design

The 1297 is built with precision-formed contacts and high-quality materials such as high-temp thermoplastics resistant to deformation under pressure. It’s not just about having a good spec sheet; it’s (literally) about being able to survive in the real world. - Low insertion force, secure retention

You want the pin to go in clean, grip, and to stay that way. The 1297’s internal geometry is engineered to be a delicate balance between easy insertion and powerful mechanical retention, even in the presence of vibration such as an automotive control unit or industrial machine. - Minimal footprint

Space is always a premium on PCBs. This connector receptacle was designed with a small footprint so you can pack more function into a smaller board, without compromising current-carrying capacity.

If you’re wondering how that compares to your current hardware, it might be time for a reality check.

Use cases where it shines

We’ve seen this circuit board connector used in a variety of high-power applications, including:

- EV power distribution boards

Where conductivity is just as important as thermal stability and long-term reliability. - Motor controllers

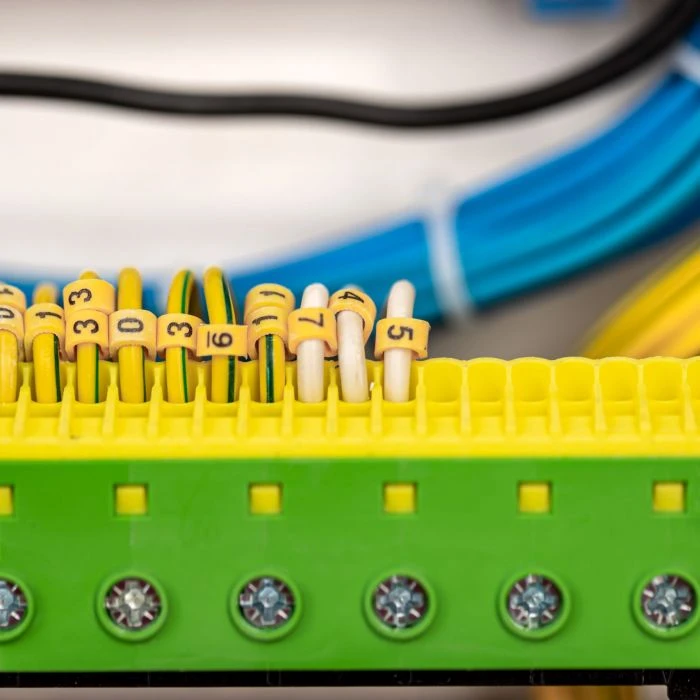

Where surges are frequent, and connectors must remain tight under vibration. - Industrial control systems

Where boards run 24/7 and connectors must endure constant stress. - Battery management systems

Where precision and minimum voltage drop are critical to performance.

So yeah, it’s more than a socket. It’s a lifeline.

Why materials and contact shape matter

If you’re in procurement or engineering, you already know the devil’s in the details. The metal used in a pin socket electrical connector is just as important as the design itself.

Zierick’s Product 1297 uses materials chosen for conductivity, corrosion resistance, and strength under thermal expansion. You want those pins to stay consistent under high heat and repeated cycling, and this high-current PCB design delivers.

It’s not just “metal” and “plastic.” It’s engineered interaction between conductive surfaces that ensures a solid electrical path even when life gets messy (and by messy, we mean hot, dusty, or full of vibration).

What to watch for when sourcing high-current PCB connectors

You’ve probably seen the listings. “High amp socket.” “Heavy-duty pin.” But let’s be honest, a lot of those off-the-shelf parts are vague at best.

If you’re buying on spec alone, you could be walking into trouble.

So what should you look for?

- Amperage rating (continuous, not just peak)

- Operating temperature range

- Plating and contact finish (tin vs. gold vs. nickel—each has its place)

- Insertion and extraction force (especially for field-serviceable units)

- Board compatibility and footprint

- Certifications or compliance standards

And most importantly: supplier reliability.

Why a U.S.-based supplier still matters

We get it, cost pressures are real. But sourcing from unverified suppliers overseas comes with real risk. Misrepresented materials, inconsistent quality, and long lead times can kill a project.

With Zierick, you get traceable, documented specs. Real support. And a connector that’s made to do the job, backed by decades of experience in the electronics manufacturing space.

It’s not just a better product. It’s a better process.

Let’s recap

If you’re working with high-current PCBs, don’t gamble on general-purpose pin receptacles.

Instead, here’s what you need:

- A socket rated for continuous high load

- Engineered materials that resist heat, oxidation, and fatigue

- A secure, reliable fit that won’t wiggle loose or degrade

- Tight specs, traceable sourcing, and responsive support

That’s what Zierick’s Product 1297 delivers. And yes, you can browse full details, mounting styles, and downloadable datasheets right here.

When every amp counts, don’t settle for less

In today’s high-performance devices, a bad connector is more than an inconvenience. It’s a weak link that can derail an entire system.

So if you’re designing or sourcing for EV, industrial, or high-power tech, make sure your high-current PCB receptacle is up to the challenge.

Zierick’s been delivering on that promise for over 100 years.

Have a look at our high-current PCB connectors and get in touch if you need custom options or guidance. Our team of engineers is at your disposal to make sure you get it right the first time.