Surface Mount vs. Through-Hole: Which Assembly Method Should You Choose?

Let’s say you’ve got a product in development. It’s sleek. It’s compact. And it needs to work reliably, affordably, at scale.

The question you’re probably asking: Do I go with surface mount or through-hole components?

Spoiler: there’s no one-size-fits-all answer.

Both have their place. Both have trade-offs. The key is knowing when and why to use each.

So let’s break it down in plain language.

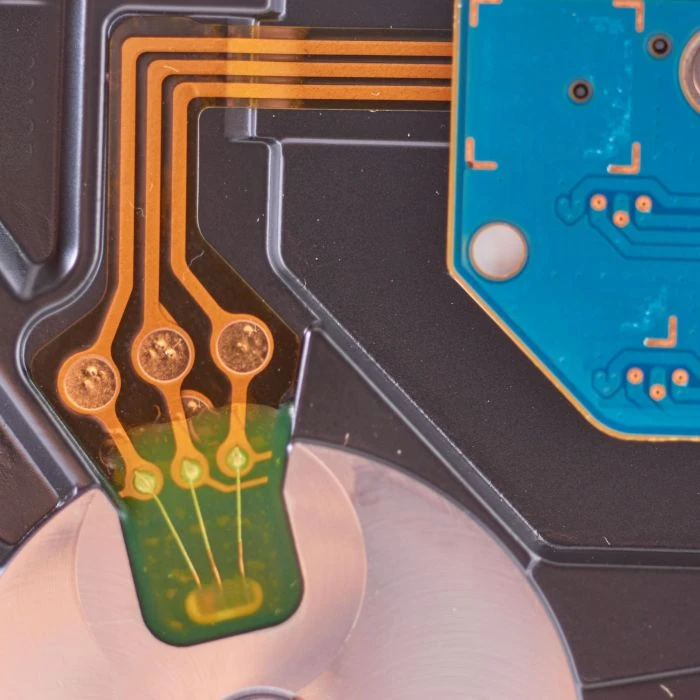

SMT 101: What exactly is surface mount technology?

Surface mount technology (SMT) is exactly what it sounds like. Instead of inserting component leads into drilled holes (like you do with through-hole), SMT components are mounted directly onto the surface of the printed circuit board (PCB).

No leads sticking through the board. No extra drilling. Just compact components, soldered flat against the surface.

This makes SMT ideal for:

- Dense circuit layouts

- Automated assembly lines

- Lightweight, space-constrained designs

Think smartphones. Laptops. Medical sensors. Anything that needs high-performance in a tight package.

How SMT evolved past through-hole

Through-hole technology used to be the standard. Everything (resistors, capacitors, ICs) had leads that threaded through holes in the board, then got soldered in place. It worked, but it took time. And space.

Then the industry started demanding smaller devices. Faster production. Lower costs. That’s when SMT stepped in.

Over the last few decades, SMT has become the go-to method for mass production. Meanwhile, through-hole is still hanging on where it makes sense.

You’ll see both in use today, but for different reasons.

Where Surface Mount Technology (SMT) shines

Let’s look at why SMT is so popular across electronics manufacturing companies.

Miniaturization

SMT components are tiny. They don’t need holes drilled into the board, which saves valuable real estate. You can fit more on a smaller board—critical for portable electronics.

Automation-ready

SMT is tailor-made for automated assembly. Machines can place and solder thousands of components per hour. That means faster builds and lower labor costs.

Lower overall cost

Less material. Less labor. Less manual assembly. SMT offers serious savings when you’re building at scale.

Versatility

You can design multi-layer PCBs with components on both sides. That opens up tons of possibilities for engineers and product designers.

But SMT isn’t perfect

Just because SMT is the modern standard doesn’t mean it’s always the better option. Let’s talk about a few limitations.

Heat sensitivity

SMT components are more sensitive to heat stress during soldering. They’re also trickier to rework if something goes wrong. That’s a headache during prototyping or repairs.

Mechanical strength

Because SMT components sit on the surface, they’re not as physically strong as through-hole counterparts. If you need to withstand vibration, force, or regular plugging and unplugging, SMT alone might not cut it.

Harder to inspect or debug

No visible leads. Smaller pads. SMT makes it harder to manually inspect, test, or troubleshoot a faulty board.

So… is through-hole old school? Or still useful?

The case for through-hole (yes, it still has one)

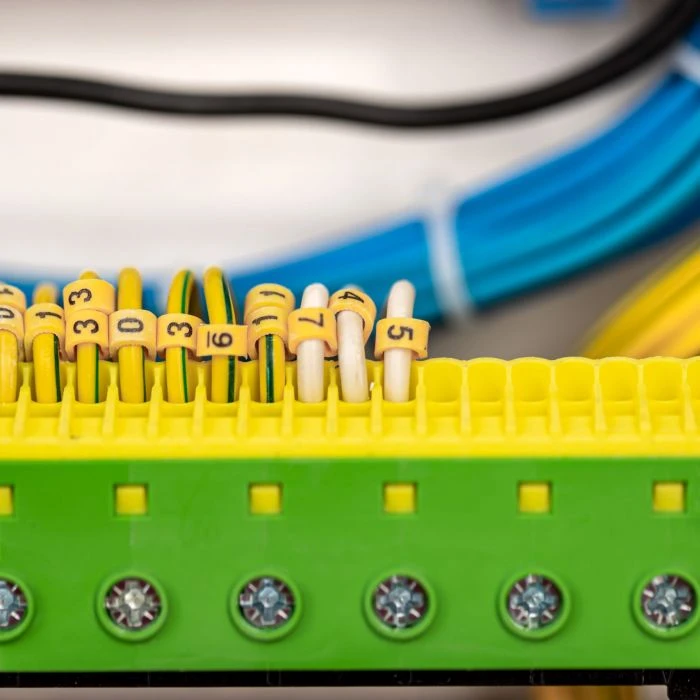

Through-hole assembly might be older, but it’s not outdated. In fact, some applications still rely on it, hard.

Superior mechanical strength

Since leads go through the board and get soldered on the opposite side, the connection is physically stronger. That matters in high-vibration environments, like:

- Automotive assemblies

- Aerospace controls

- Heavy industrial machinery

Ideal for prototyping

Through-hole components are easier to swap out, test, or adjust on the fly. That’s why hobbyists and R&D labs still love them.

Better for connectors, switches, and high-power parts

Need to plug something in or run high current? Through-hole is often the safer bet.

SMT vs. through-hole: when to choose what

This isn’t a battle. It’s a decision.

Here’s how to choose between SMT and through-hole:

| Factor | Choose SMT if… | Choose through-hole if… |

| Space is limited | You need compact layouts and dense circuits | You can afford larger boards |

| Volume production | You want high-speed, automated assembly | You’re building in low volume or manually |

| Mechanical durability needed | Your board sits in a stable enclosure | The part gets jostled, plugged, and unplugged often |

| Prototyping or repair | You’re designing for scale | You need to test, tweak, or rework regularly |

Sometimes, you don’t choose. You combine.

The hybrid approach

Many modern assemblies use both SMT and through-hole components on the same board.

It’s called a hybrid PCB, and it’s common in:

- Consumer electronics

- Medical devices

- Automotive ECUs

Here’s how it typically works:

- SMT for compact ICs, resistors, and capacitors

- Through-hole for larger parts like connectors, switches, and power components

This gives you the best of both worlds: space savings, plus strength where you need it.

Zierick, for example, offers both surface mount tabs and quick disconnect terminals and through-hole options to support hybrid builds. You get flexibility without compromising performance.

Where SMT is used (and why)

Let’s get real. SMT isn’t just a cool tech choice. It’s everywhere.

- Consumer electronics: phones, tablets, headphones

- Automotive: ECUs, sensors, infotainment

- Aerospace: navigation systems, engine monitors

- Medical: pacemakers, glucose monitors, diagnostic tools

- IoT: smart sensors, connected devices, wearables

In these applications, SMT’s small size, cost efficiency, and production speed aren’t perks; they’re essential.

Best practices when choosing SMT connectors

If you’ve decided SMT is right for your build, here are a few quick tips:

- Match the pitch – Smaller pitch means more density but tougher placement

- Check current ratings – SMT connectors don’t always handle high loads

- Use ESD-safe packaging – Protect components during handling and shipping

- Plan for inspection – SMT assembly can hide defects

- Choose the right supplier – Zierick’s SMT connector options are built for reliability, repeatability, and spec-backed performance

What’s the right move for your build?

If you’re building the next big thing (or trying to avoid the next big headache), the decision between surface mount and through-hole matters.

It’s not about what’s trending. It’s about what fits your product, your environment, and your production goals.

So ask yourself:

- How much space do you have to work with?

- How durable does the assembly need to be?

- Are you building a few units or thousands?

- How often will these parts be handled, repaired, or replaced?

When you’ve got those answers, your connector choice becomes clearer.

Explore Our Surface Mounts at Zierick!

Still unsure? Explore Zierick’s catalog or reach out to our engineering team. We’ll walk through the specs with you, no guesswork, just smart design support.