Let’s say you’re deep into a PCB design. You’ve got your layout tight, your component list dialed in, and now it’s time to choose your connectors.

Surface-mount? Through-hole? Something hybrid?

If you’re leaning toward SMT connectors but still have questions (especially about SMT Faston tabs), you’re in the right place. This guide won’t flood you with jargon. Instead, we’ll concentrate on what matters most for real-world builds: space, speed, and reliability, as well as sourcing parts that won’t suddenly let you down mid-production.

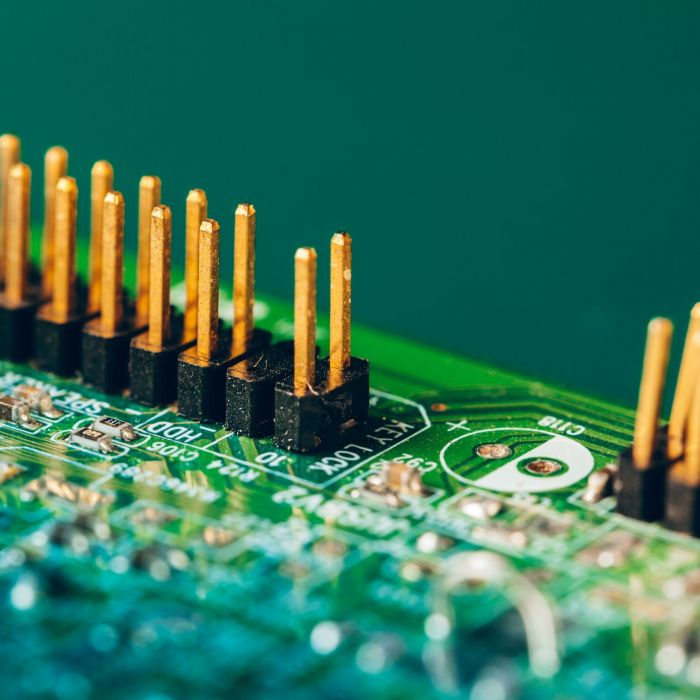

First, what are SMT connectors?

SMT (surface-mount technology) connectors are exactly what they sound like: board-level components that mount directly onto the surface of a PCB—no drilled holes, no long leads. You’ll usually spot them in:

- Consumer electronics (phones, wearables, tablets)

- Automotive modules

- Industrial sensors

- Power supplies

- Control panels and HVAC systems

Instead of passing through the board, an SMT surface mount connector sits flush on the surface, attached via solder paste and reflow soldering. That design allows for smaller PCBs, higher-speed production, and tighter control over signal paths.

Why SMT surface-mount connectors have taken over

SMT beats through-hole connectors on a few big fronts:

- Miniaturization: They require less real estate. More can fit into smaller footprints.

- Automation-compatible: SMT components are suitable for pick-and-place mounting, and can speed up high-volume assembly.

- Signal integrity: Performance enhanced (shorter paths) and less interference at high-speed applications.

- Cost-efficiency: Less steps = less labor (time) and fewer manual errors.

Bottom line? With these SMT connectors, you can design smarter and build faster, especially in high-density applications.

Common types of SMT connectors you’ll see on a board

There’s no one-size-fits-all here SMT connector. Depending on your application, you might need:

- Headers and receptacles: Board-to-board or board-to-wire connections.

- Battery connectors: For portable devices or power backups.

- RF connectors: For high-frequency signals in IoT and wireless systems.

- Terminal blocks: In industrial or building automation projects.

Each has a role. But when you need a quick-disconnect option for power or signal, especially one that can handle vibration and current, Faston tabs shine.

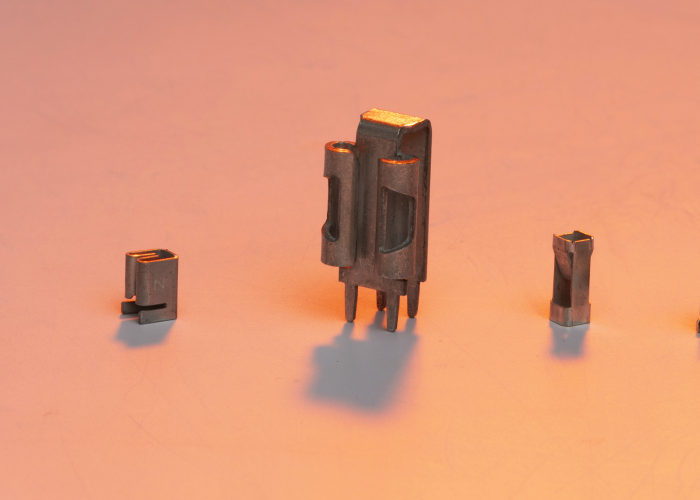

Let’s talk about SMT Faston tabs

Most engineers are familiar with classic Faston terminals: they’re the ones that join blade connectors in household appliances, control systems, or on a car dash. But the SMT Faston tab extends that same dependable, quick-disconnect answer to surface-mount applications.

So what makes SMT Faston Tabs different?

- Surface-mount design means no through-holes, preserving signal integrity and reducing assembly time.

- Quick-connect/disconnect capability is great for modules that require serviceability.

- Low profile makes them ideal for tight spaces and compact enclosures.

- High reliability even under vibration or thermal stress.

Zierick’s SMT Faston tab connectors are designed to address these types of applications. They bring you strength and consistency, and allow for a quick building process with minimal decay of board space.

SMT vs. through-hole: which one’s right?

The truth is, there’s still a place for through-hole. It all comes down to application.

|

Feature |

SMT Connectors |

Through-Hole |

|

Space-saving |

✅ |

❌ |

|

Automation-ready |

✅ |

❌ |

|

Vibration resistance |

✅ (with reinforcements) |

✅ |

|

Mechanical strength |

Good |

Excellent |

|

Reworkability |

Easier |

Harder |

|

Cost per unit (mass production) |

Lower |

Higher |

If you need rugged mechanical anchoring, through-hole may still be your best bet. However, at high-volume productions with tight tolerance requirements, SMT connectors provide the right combination of speed and performance.

Choosing the right SMT connector: key questions to ask

Before you click “order” on your chosen SMT connector, slow down and ask:

- What’s the current rating? Will the connector handle your load?

- What’s the pitch and footprint? Will it fit your board layout?

- What’s the mating cycle rating? Some connectors wear faster than others.

- Do I need vertical or right-angle placement? Orientation affects clearance and cabling.

- How will it be inspected? Choose connectors compatible with your quality control process (AOI, X-ray, etc.).

Don’t forget to check for compliance specs too—especially if you’re building for medical, automotive, or aerospace environments.

Handling and assembly: don’t wing it

You’d be surprised how often a solid connector fails because of poor handling. Here are a few reminders:

- Use ESD-safe trays when handling connectors pre-placement

- Avoid excessive heat during reflow. SMT Faston tabs can take it, but overdoing it stresses the solder joint

- Inspect joints post-reflow for bridging or cold soldering

- Use reinforced packaging to avoid bent terminals during shipping

The more you build SMT connectors into your workflow, the easier it gets. Just don’t skip the inspection phase. Even a tiny solder crack can trigger a long debugging session later.

Real-world use cases for SMT Faston tabs

If you’re sourcing for:

- Industrial control panels

- Power supplies or converters

- HVAC control systems

- High-speed routers or servers

- Test equipment or diagnostics gear

…then SMT Faston tabs can save space, simplify rework, and hold up under heavy cycles.

They are particularly useful in applications that will be assembled and occasionally disconnected without the use of bulky components. That’s why OEMs across consumer electronics and heavy industry rely on them.

Wrapping it all together

An SMT surface mount connector isn’t just a design decision—it’s a production decision. And with SMT Faston tabs, you’re getting speed, strength, and smart use of board space.

If you’re in procurement, here’s what to prioritize:

- Surface-mount components with proven durability

- Verified ratings for current, temp, and vibration

- A supplier who can actually support your timeline

Zierick offers precision-engineered SMT Faston tabs backed by decades of real-world performance data. We design for manufacturers who don’t have time for rework and need solutions that ship on spec, on time, and ready to handle stress.

Want to build better boards?

Start with the connectors that make everything else possible.

Browse SMT Faston tabs from Zierick.

Questions about fit, function, or customization? Let’s talk.