SMT Surface Mount Technology Explained: Benefits, Challenges & Best Practices

Electronics today are faster, smaller, and more powerful than ever. Behind that evolution is a manufacturing method that changed everything: surface mount technology.

If you’re running a small electronics business or tinkering as a maker, understanding how SMT surface mounts works (and how it stacks up against traditional methods) can help you build smarter, more efficient products. This guide walks you through what SMT is, why it’s used, where it shines, and what to watch for when designing or assembling your own boards.

Let’s start with the basics.

What is SMT?

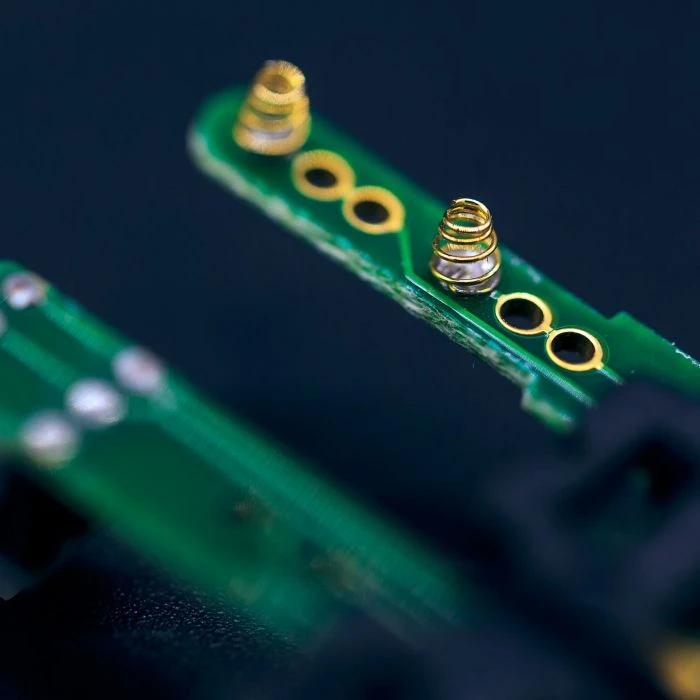

The term SMT (Surface Mount Technology) has been used to describe the process of affixing components onto the surface of a printed circuit board (PCB). SMT is different from older through-hole methods in that it doesn’t require electronics to be passed through holes in the board. The result: quicker production, more compact form factors, and increased design flexibility.

SMT had its start in the 1980s when manufacturers sought ways to pack more components onto circuit boards but without increasing the size of the board. When they shrank, so did the requirement for finer placement and soldering methods. However, as we stand today, SMT is now the primary assembly process utilized in the vast majority of the electronics industry.

Surface mount vs. through-hole: What’s the difference?

When it comes to surface mount vs. through-hole, the main difference is how the components are affixed to the board.

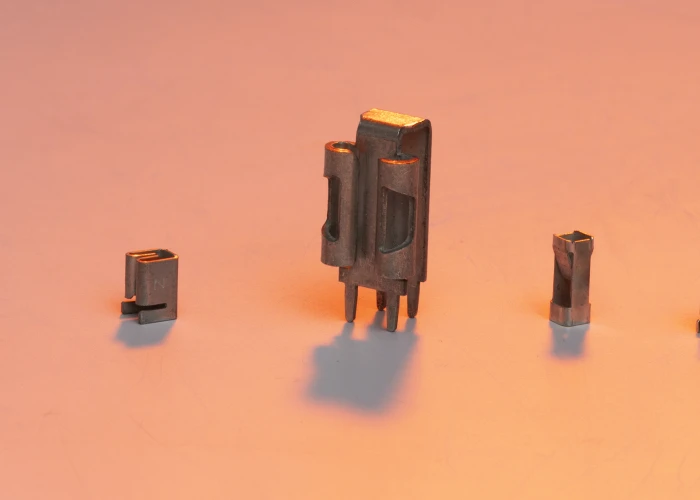

With through-holes, the leads of components are inserted in holes drilled through the board and then are soldered to pads on the other side of the board. It has such good mechanical stability that it is still used in high-stress applications—say, aerospace or military.

Surface mount components, by contrast, are soldered directly to pads on the PCB’s surface. No holes. Just clean, efficient contact.

Here’s a quick comparison:

| Feature | Through-Hole | Surface Mount |

| Mounting Method | Inserted into holes | Soldered to surface |

| Component Size | Larger | Smaller, more compact |

| Assembly | Often manual | Fully automated |

| Mechanical Strength | Higher | Moderate |

| Board Density | Limited | High-density layouts |

| Cost | Labor-intensive | More cost-efficient at scale |

If you’re prototyping or need durability, through-hole might be the better fit. But for modern, space-conscious designs? SMT is usually the way to go.

Top 5 benefits of SMT surface mount technology

There’s a reason why surface mount is dominant in today’s electronics industry. Here are five standout advantages:

1. Smaller component size

SMT components are tiny compared to their through-hole counterparts. That means more parts can fit on a single board, essential for modern devices like smartphones and wearables.

2. Higher board density

No drilling required, can be used on both sides of a PCB. That lets designers pack more into less space, leading to more compact and efficient products.

3. Faster assembly

SMT is tailor-made for automation. Components can be placed with pick-and-place machines, then soldered all at once during reflow soldering. This speeds up production and reduces labor costs.

4. Lower overall cost

Less drilling, faster placing, and compatibility with automated lines mean real savings when you look at large volume projects.

5. Better electrical performance

A shorter lead also means less inductance and resistance, which might save a little when maximizing high-speed signal integrity and overall circuit efficiency.

Common SMT production challenges and how to solve them

SMT has had its own quirks, like any technology. And if you’re a small business owner or DIY electronics maker, it’s useful to know what can go wrong and how to avoid it.

Solder bridging

This occurs when excess solder creates a bridge between two adjacent pads, shorting the circuit. It’s often caused by too much solder paste or improper stencil alignment.

How to fix it:

- Use high-quality stencils with the right aperture size

- Calibrate your paste dispensing or printing equipment

- Double-check pad spacing in your PCB design

Tombstoning

This happens when one side of a small component (like a resistor) lifts up during reflow, making it look like it’s standing on end. Tombstoning results in poor or no electrical connection.

Prevention tips:

- Balance the heat distribution during reflow

- Ensure pad sizes and paste volumes are consistent

- Asymmetrical pad designs should be avoided in this case.

Misalignment

If a part is placed off-center, it’s wise to assume it might not connect correctly after soldering. Misalignment can be due to vibration, nozzle pressure, or static electricity.

Solutions:

- Keep your pick-and-place machine well-maintained

- Use components marked with clear polarity and tight tolerance.

- Then use fiducial marks on your board to achieve machine alignment.

PCB design best practices for SMT

To make the most of your surface mount implementation, your PCB layout and assembly process must be spot on. Here are a few essential tips:

Use proper pad sizes and spacing

Each component has a recommended land pattern. Stick to it. Overly large or small pads can cause defects during reflow.

Optimize stencil design

The stencil controls solder paste application. Use stainless steel stencils with laser-cut apertures for consistent deposition. Adjust thickness based on component size and pitch.

Plan for reflow soldering

Reflow is the standard soldering process for SMT. Your PCB stack-up, component placement, and solder paste must be compatible with a predictable thermal profile.

Keep thermal relief in mind

Place heat-sensitive components away from large copper pours, and consider using thermal vias to manage hotspots.

Include test points

Even in surface mount designs, testing matters. Add accessible test points for debugging, especially during prototyping.

Is SMT right for your next project?

If you’re building compact, modern electronics, and you want to scale efficiently, SMT surface mount is probably the right fit. That said, for the hobbyist or specialized equipment which demands a rugged design, a mix of SMT and through-hole can be a nice compromise.

Zierick provides both surface mount and through-hole hardware options, allowing you to select the best design for your application and your assembly process. If you are looking for simple integration and equipment compatibility, our SMT terminal solutions are engineered for you. If your design calls for traditional ruggedness, we also provide through-hole tabs and terminals.

Get SMT Surface Mounts with Zierick

Mastering SMT doesn’t happen overnight, but it’s worth the effort. Whether you’re a startup building wearables or a seasoned engineer optimizing your assembly process, understanding SMT’s strengths and common pitfalls puts you ahead.

As electronics continue to get smaller and more complex, surface mount technology will remain a crucial part of the manufacturing conversation. Staying up to date on best practices, design considerations, and trusted suppliers can make the difference between a reliable product and one that fails in the field.

Ready to take your board designs to the next level with high-performance SMT connectors? Experience Zierick’s full SMT catalog and find solutions built for the real builders.

Because in electronics, every detail matters, and every connection counts.