There are certain components that don’t make the spotlight, but everything stops without them. The 187 Faston tab is one of those parts — small, reliable, and used almost everywhere electricity moves.

It’s the connection you don’t think about until it fails, and that’s exactly why it deserves attention.

What the 187 Faston Tab Actually Is

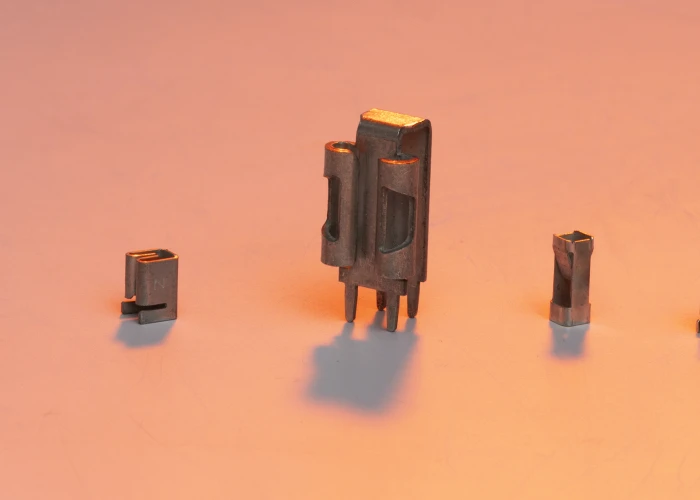

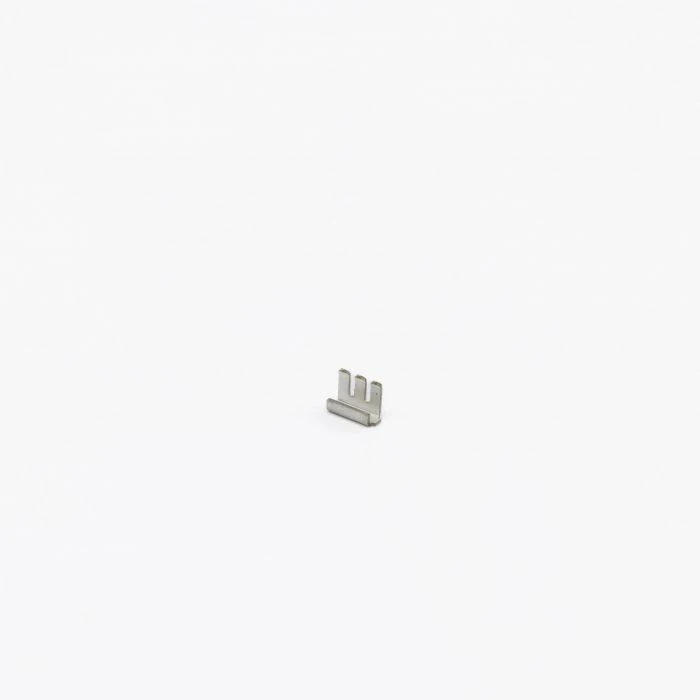

In simple terms, it’s a quick-disconnect terminal that measures 0.187 inches wide (about 4.75 mm). That might sound minor, but that dimension is what makes it perfect for compact electronics and automotive systems where space is tight but dependability is non-negotiable.

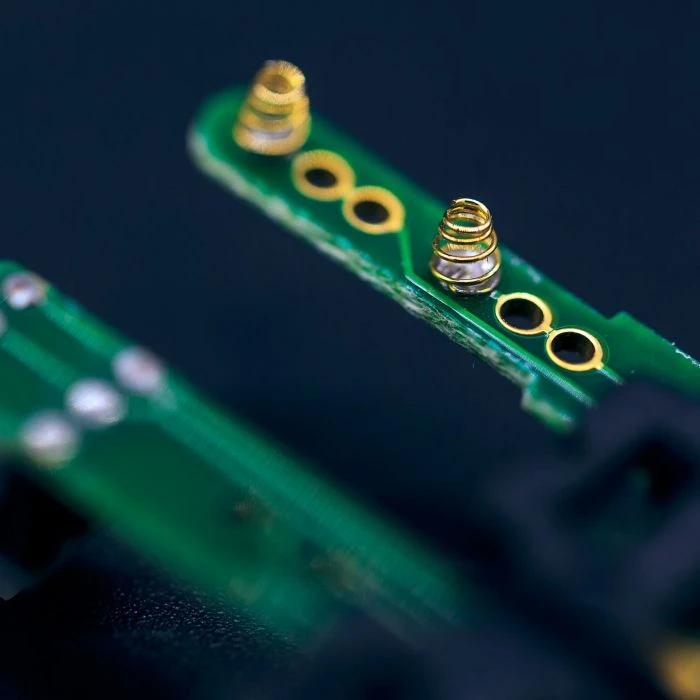

The 187 Faston tab’s design allows for repeated connections and removals without losing tension, making it ideal for systems that need maintenance access. Zierick’s Press-Fit Series 956 improves on that concept with a press-fit design that holds firm without soldering, saving both time and rework on the assembly line.

Common Applications for 187 Faston Tabs

187 Faston tabs are all over the place once you start looking.

- Automotive systems: control panels, sensors, and small motors all use 187 tabs to keep wiring tight under vibration.

- Electronics: inside lighting fixtures, power supplies, and PCB assemblies where size matters.

- Appliances: quick connections for switches, thermostats, and low-voltage controls.

- Industrial controls: helping maintenance crews make fast swaps without heating tools or re-crimping wire ends.

Every one of these industries depends on connections that stay solid even in rough conditions. The 187 Faston tab delivers that consistency in a size small enough for modern designs.

Installation Tips for 187 Series Terminals

Installing 187 Faston tabs isn’t complicated, but small mistakes can cost time and reliability. A few reminders go a long way:

- Match the wire gauge — too thick or too thin and the connection won’t hold or conduct properly.

- Clean contact points — oxidation or dirt increases resistance, which leads to heat buildup.

- Avoid over-crimping — more force isn’t better; it can deform the tab and weaken the joint.

- Check alignment — the mating connector should slide on snugly, not jam into place.

Always inspect the finished connection. A quick pull test can tell you more about stability than any visual check.

187 Faston Tabs vs. Other Faston Sizes

Compared to the popular 250 Faston tab, the 187 size trades a little current capacity for tighter spacing. It’s the compact version that fits where the larger one won’t — perfect for low- to mid-power applications or boards with high component density.

Bigger tabs like 312 or 375 handle heavier loads, but they eat up more space. The 187 sits right in the sweet spot: small footprint, reliable grip, steady performance.

Getting the Most Out of Every Connection

Good connectors last when materials and handling align. Tabs made from brass or phosphor bronze with tin or nickel plating resist corrosion and maintain conductivity through thousands of cycles.

Zierick’s parts are built for that exact balance. Dependable conductivity and easy integration into automated production. If you’re designing a compact assembly or upgrading existing wiring, explore the Press-Fit Series 956.

It’s proof that reliability doesn’t have to be big or complicated, just well-engineered.