What is an SMT Connector and Why It Matters in Modern Electronics Manufacturing

If you’ve ever pried open a smartphone, peered inside a computer, or you know, used your car’s infotainment system, you’ve seen them — little rectangular components that sit on the surface of a circuit board, like a biscuit resting on a tablecloth. They may not look like much, but they’re doing some of the heaviest lifting in modern electronics. Welcome to the world of SMT connectors.

In today’s electronics manufacturing landscape, SMT connector options are foundational. From high-volume consumer electronics to critical industrial systems, these compact, efficient components help shrink footprints, speed up production, and improve performance. But what exactly are they? And how do they stack up against more traditional kinds of connections?

Let’s unpack the essentials and give you a solid foundation for sourcing the right SMT solutions for your next build.

First, what is SMT?

SMT is the acronym for Surface Mount Technology, which is used when electronic components are to be mounted directly onto the surface of printed circuit board (PCB). Whereas the older process required holes to be drilled into the board (through-hole technology), SMT skips that.

That one change has single-handedly revolutionized the electronics industry. Smaller parts, more reliable connections, and better support for automation. It’s a game changer. And connectors designed for SMT, such as an SMT faston tab or other surface-mount tabs, are a primary part of that trend.

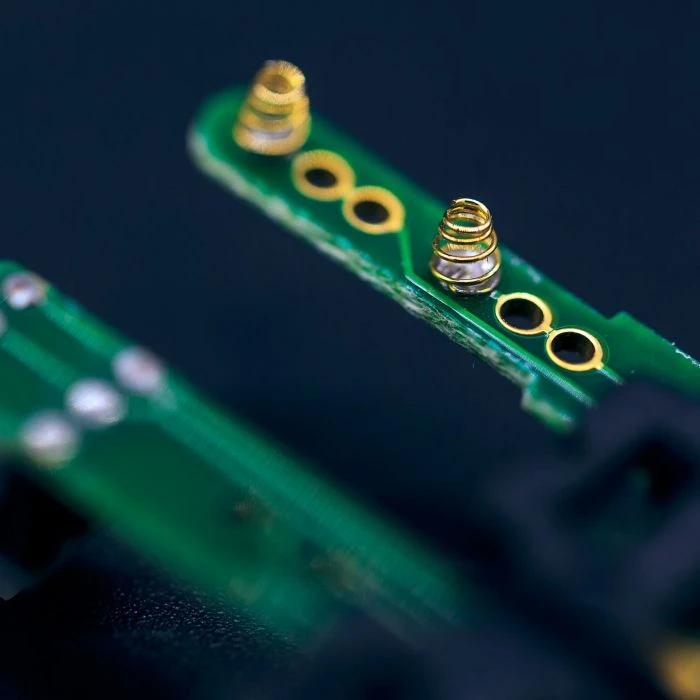

So, what is an SMT connector?

An SMT connector is any electrical connector designed specifically for surface mounting. These connectors don’t go through the PCB. Instead, they’re soldered directly to the copper pads on the board’s surface. The end result is a low-profile, space-saving connection that still manages power, signal, or ground just as well.

Some connectors are still used in both SMT and through-hole formats, but SMT versions are generally preferred for automated manufacturing lines where precision, speed, and compact designs are priorities.

SMT faston tab connectors: Built for modern speed

One subtype of SMT connectors worth calling out is the SMT faston tab. They are surface mount terminals designed for the rapid connection of wires and are used in quick disconnect circuits. The tabs at each end of the plug provide a positive mechanical connection, and the surface-mount base keeps the connector flat against the board.

You’ll frequently see these in power supplies, lighting systems, HVAC controls, or many applications where you need a clean, replaceable, and quick electrical connection.

Zierick’s SMT faston tab line includes multiple sizes and tab widths, all designed for surface-mount compatibility with automated pick-and-place machines. Browse them here.

SMT vs through-hole: What’s the difference?

It really depends on how things are connected to the PCB. Through-hole components have leads that feed through to the other side of the board where they are soldered in place. This is a very robust mechanical bond. This is why through-hole still sees much use in aerospace, military, or high-stress applications.

But SMT? SMT is speedier, more space-efficient, and the most appropriate for today’s automated assembly lines.

Here’s how they stack up:

| Feature | Through-Hole | Surface Mount (SMT) |

| Size | Larger components | Smaller, more compact |

| Assembly | Manual or semi-automated | Fully automated |

| Board Design | Requires holes | No holes required |

| Mechanical Strength | Stronger | Moderate, but sufficient |

| Cost Efficiency | More labor-intensive | Lower cost per unit at scale |

That last point, cost per unit, matters a lot in high-volume production. SMT wins every time in terms of automation and total assembly efficiency.

Where are SMT connectors used?

Short answer: almost everywhere. But here are a few specific places you’ll find SMT surface mount connectors:

- Consumer electronics: smartphones, tablets, wearables

- Industrial equipment: motor controllers, factory automation systems

- Automotive electronics: ECUs, dashboard systems, sensors

- Telecom: routers, signal processors, and network devices

- Home appliances: smart thermostats, washers, lighting systems

The compact footprint of SMT connectors allows engineers to design smaller, more powerful boards without sacrificing performance.

Why size and automation matter

The name of the game in today’s industry is speed and scale. The greatest benefits of an SMT are found in size and automation, but this has practical implications on the manufacturing floor.

You can:

- Pack more parts onto a single board

- Smaller enclosures for narrow product designs

- Use pick-and-place machines faster

- Reduce labor and rework costs

- Enhance the consistency and the quality of your solder joints

That means it’s less expensive, per unit, for procurement teams, and less of a hassle, too. For engineers, it equates to greater freedom in board layout and product design.

What to consider when sourcing SMT connectors

Here’s what to think about before placing your next order:

- Current rating and contact resistance

Will the connector handle the load? If it’s for power, double-check the specs. - Pad layout and footprint

Make sure the connector matches your board design. A mismatch here will slow everything down. - Solderability and finish

Tin-plated or gold-plated? Each finish has trade-offs in cost, performance, and corrosion resistance. - Assembly compatibility

Can your pick-and-place machine handle the size and shape of the connector? Zierick’s SMT connectors are designed with automation in mind. - Application environment

Humidity, temperature, vibration—choose a connector that can survive in its intended use case.

Zierick’s approach to SMT connectors

Zierick has specialized in high-performance connectors and interconnect solutions for more than 100 years. Our SMT connector product range offers everything from SMT faston tabs to SMT surface-mount disconnects, when easy, reliable SMT soldering and automation compatibility are important.

Need something specific? We partner with OEMs to design custom solutions built to your spec and manufacturing capabilities.

And yes, our parts are backed by datasheets and staffed by US-based tech-support, so there’s no guesswork.

Bring your product to life with the right SMT connector at Zierick

Great parts make for great designs. The right SMT connector does more than connect power or signals; it connects your product to new possibilities, adding value, reliability, and scalability to your design.

When you need a production-ready SMT connector, turn to Zierick. Whether you design for performance or cost, or both, our new line of SMT surface mount tabs and terminals is developed to meet the requirements of today’s electronics designers.

Browse our full line of SMT connectors at Zierick.com and reach out if you’d like help determining the best fit.

Because when it comes to smarter, more efficient electronics, every connection counts.