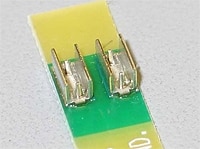

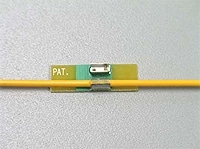

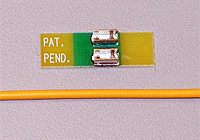

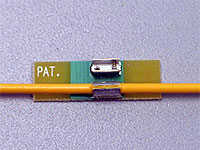

Zierick Manufacturing Corp. has developed a new family of SMT connectors. They are highly reliable and provide an economical way to connect a wire to a Surface Mount Printed Circuit Board. These innovations consist of a surface mounted insulation piercing crimp terminal and a special tool which crimps the wire into the terminal and locks it in position.

Zierick is your one source partner for our new Surface Mount Insulation Piercing Crimp Terminals, as well as application tooling and automation services. Ask us about what we can do to provide:

- Loose piece, taped and reeled Crimp Terminals

- Application tooling for small volume crimping of Crimp Terminals

- Wire stitching equipment to provide high speed automated wire feeding directly into the Crimp Terminals at the point of crimping, bypassing the need for hands-on wire handling

- Feeders to feed loose piece and reeled Crimp Terminals directly to your component placement machines, and

- Parallel crimping systems to crimp multiple wires into multiple Crimp Terminals at one time.

Additional Resources

Crimp Terminal Wins Higgins-Caditz Design Award! Read the article from PMA’s MetalForming Magazine.

Watch the Crimp Terminal movie!

Download a PDF Datasheet about our Crimp Terminal Family.

View the Test Report for our Crimp Terminal Family.

Read an Article about our Crimp Terminal Family in DesignFax (PDF).

The Recommended Center-Center Spacing PDF can be seen here.