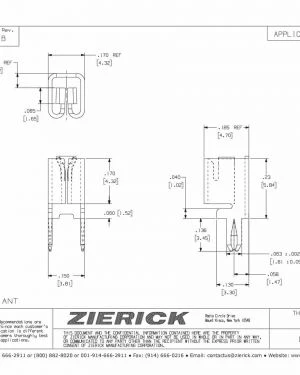

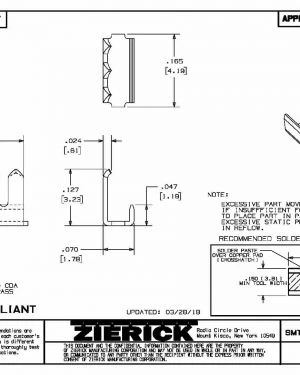

Product specifications listed on the website, catalog, or any documents that may fall under the category of promotional literature are subject to change without notice without creating liability to Zierick Manufacturing Corporation. Please contact us for the most current prints and dimensions.

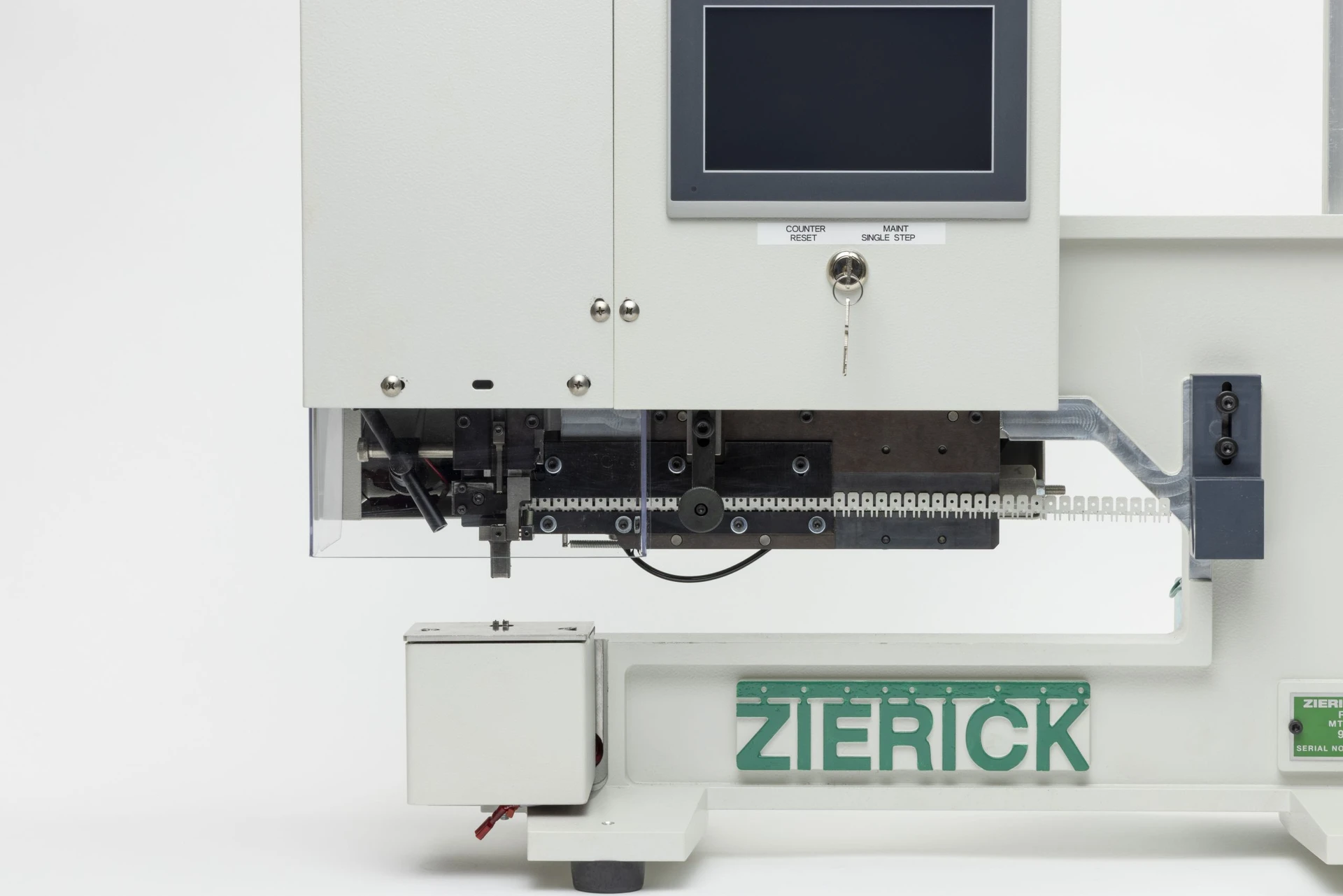

THT 9700 Gen II

Zierick has upgraded its popular Model 9700 Terminal Insertion Applicator to provide improved operation and usability.

The Model 9700 Gen II now includes a color touch screen interface that provides the operator with Onboard Screen Diagnostics. The machine also incorporates the latest version of an Allen-Bradley PLC Controller coupled with improved pneumatic cylinders and valving.

The Model 9700 Gen II is compatible with current Model 9700 Tooling and utilizes the same footprint on the Production Floor.

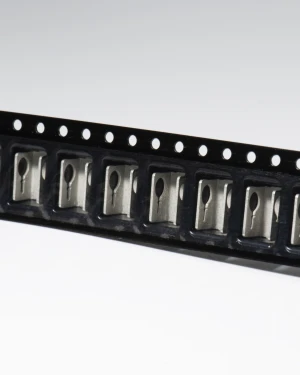

The 9700 Gen II delivers fast performance, with production rates up to 5,000 pph and inserts Zierick’s full range of thru-hole continuous strip PCB terminals and connectors.

Flexibility makes the Model 9700 Gen II ideal for production lines and manufacturers. Its sleek, compact appearance is combined with rugged yet lightweight construction. It provides dependable performance in a small bench-top footprint.This model is designed for easy operator use, set-up, alignment and terminal changeover. This is accomplished by a number of key equipment features including interchangeable applicator tooling, calibration tools for head-to-anvil alignment, fewer moving parts and accurately machined mating surfaces.

| Basic Features | Color Touch Screen Display Onboard Screen Diagnostics Interchangeable tooling Self-locating anvil/lower tooling Cycle rate up to 5,000 pph Modular head, anvil & feed Microprocessor controlled Optional CE compliance |

| Air Requirements | 90-120 PSI (6.2-8.3 bar) 8 CFM (3.8 L/s) |

| Power Requirements | 120 Vac, 50-60 Hz, 2 Amps Optional 100/240V, 50-60 Hz, 1 Amp |

| Dimensions | Length 33.5” (851mm) Depth 15” (381mm) Width 12” (305mm) Weight 118 lbs. (53.5 Kgs) Throat Depth 15” (361mm) |