If you’ve ever handled a circuit board during assembly, you already know how fragile the whole thing can feel. One wrong bend, one loose screw, or one poorly supported edge, and suddenly the board flexes in ways it shouldn’t. That’s why PCB mounting hardware exists. It keeps everything steady, aligned, grounded, and secure so the electronics can do their job without drama.

And yet, for something so critical, PCB mounting hardware is one of the most overlooked parts of circuit board design. People worry about chipsets, traces, power profiles, thermal loads — but the standoff or terminal that’s physically holding the board in place? That somehow becomes an afterthought.

Let’s fix that.

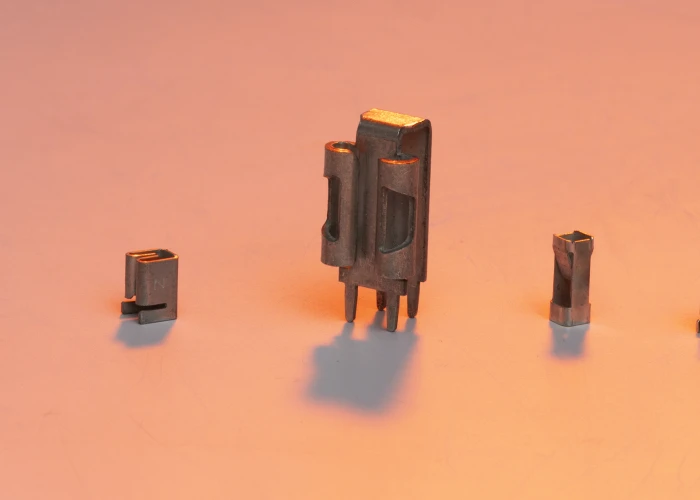

The Different Types of PCB Hardware

There’s a lot more variety than people expect. Each piece plays a specific role in keeping your pc board stable and electrically safe.

Standoffs: These are the tiny towers that lift the board off the chassis or panel. They prevent shorts, improve airflow, and stop the board from flexing under pressure. You’ll see them in aluminum, nylon, brass — depending on strength and grounding needs.

PCB board mounting clips: Useful when you want tool-free installation. They snap the pc board into place without screws. Great when you need quick replacements or frequent servicing.

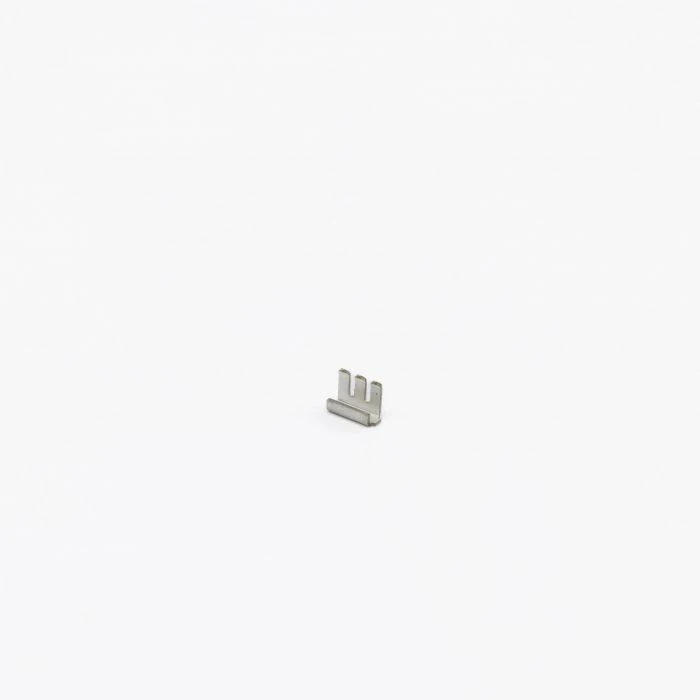

PC board terminals: These give you electrical connection points on the mainboard PCB or smaller boards. They’re part mechanical support, part electrical path.

Mounting brackets and tabs: Heavier boards or boards with large connectors often need extra structural reinforcement. These pieces keep things from shifting when someone plugs or unplugs a cable.

Zierick offers several options in its circuit board PCB hardware lineup if you need parts that hold up under industrial use.

Best Practices for Mounting PCBs

A perfectly designed board can still fail if it isn’t mounted properly. A few habits make a big difference in long-term performance.

Support the board at its stress points. Corners, connector areas, and heavy component clusters need stable contact with the chassis or enclosure. Leaving one of those areas “floating” is a guaranteed flex point.

Use the right standoff height. Too tall and the board wobbles. Too short and you risk scraping the underside of the PCB against the housing.

Avoid overtightening. Lots of cracked boards come from screws cranked down harder than needed. Tight enough to hold, loose enough to let the board breathe during thermal expansion.

Consider vibration early. Automotive, HVAC, and industrial environments punish PCBs. PCB mounting hardware should match that environment, not fight it.

Choosing the Right PCB Mounting Hardware for Your Board

Different boards need different solutions. A lightweight PCB mainboard with mostly digital components doesn’t need the same support as a power board driving motors or transformers.

Look at:

- Board thickness

- Weight distribution

- Whether connectors require push or pull force

- Need for electrical isolation versus grounding

- Temperature cycling and airflow

If your printed circuit board hardware isn’t matched to your actual operating environment, performance will suffer no matter how good your electronics are.

Grounding and Electrical Safety

It’s easy to forget that mounting hardware sometimes doubles as part of the grounding strategy. Metal standoffs can provide a safe path to chassis ground, which helps reduce noise, improve EMI tolerance, and protect sensitive circuits.

Plastic standoffs, on the other hand, completely isolate the board. That’s useful when grounding through the frame might cause interference or routing issues.

Know what your board needs before you choose.

Keeping PCB Mounting Hardware in Good Shape

Good hardware lasts a long time, but nothing lasts forever. During regular maintenance, check for:

- Loosened screws

- Oxidized terminals

- Warped mounting points

- Cracked plastic clips

- Standoffs with stripped threads

These small problems snowball into unreliable connections or uneven board pressure.

Replacing hardware costs pennies compared to repairing a damaged board.

A strong design always includes strong circuit board mounting hardware. If you’re building something that needs to hold up under heat, vibration, or continuous use, it pays to choose parts that were built with those realities in mind.

Take a look at Zierick’s full range of PCB hardware components, and you’ll find standoffs, terminals, and mounts designed for real-world conditions, not just clean bench setups.