Choosing the Right Lug Solder Lug Terminal Connector Size for Your Project: A U.S. Buying Guide

Finding the right solder lug terminal connector may not seem complicated at first. But when you’re managing current loads, ensuring long-term reliability, and trying to stay within U.S. specs, the size and type of terminal you choose matters more than you think.

If you’re a procurement manager, engineer, or technician sourcing terminals for U.S.-based manufacturing or repairs, choosing the correct solder lug terminal lug connector solder type is key to safety, performance, and compatibility. This guide walks through how to choose the right size based on wire gauge, current ratings, and application needs. We’ll also touch on the differences between long and short lug terminals, how standards like AWG and MIL specs come into play, and where to find trusted spec sheets for your next project.

Let’s break it down in a way that’s actually useful, without the jargon overload.

What is a solder lug terminal connector?

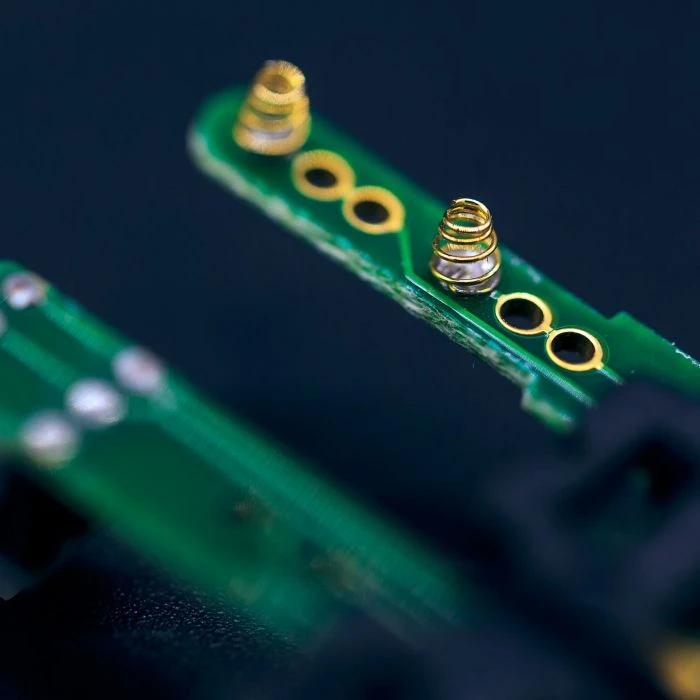

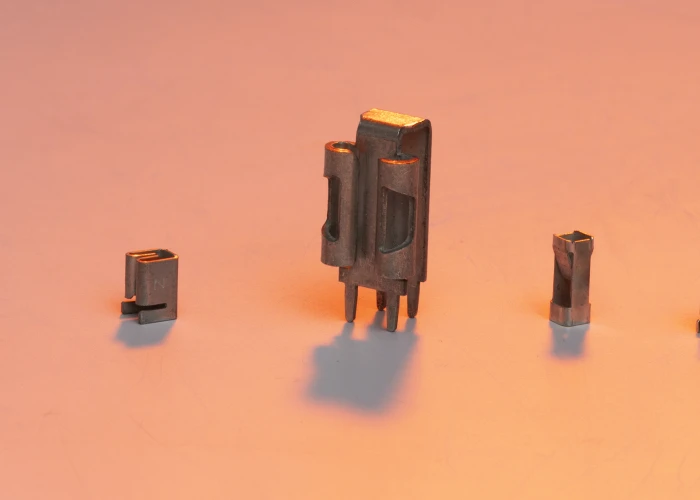

The solder lug terminal connector is a low-cost component that can be employed to make a soldered connection of a lead wire to a post, terminal block, or to any desired point where electrical grounding is desired. It consists of a flat metal tab, called a “lug”, the plate (that bolts to the case), a small hole (for a mounting screw), and a solder tag.

They’re used in switches, industrial controls, audio gear, or anything else that requires a durable, low-resistance mechanical connection that will not shake itself loose over time. You will also find them in scenarios where crimping is impractical or it’s a tight squeeze.

Wire gauge and current: Why size really matters

The lug size should be your primary concern when selecting a solder lug terminal – it needs to be correctly sized to fit your wire gauge and the amount of current it must conduct.

In the United States, we rate wire size in terms of AWG (American wire gauge). The smaller the AWG value, the thicker the wire will be, and the greater its current-carrying capacity. The lug hole needs to be fit to the wire’s outer diameter, and the contact area must be large enough to handle the current without melting.

Here’s a quick rule of thumb:

- 22–18 AWG will normally get down to small terminals with less than 5 amps.

- 16-14 AWG usually are rated for 10–15 amps.

- 12–10 AWG wires are for heavier loads, 20 amps and up.

But these are just ballpark figures. Always check the datasheet or spec sheet for your specific terminal to confirm the exact current rating.

Zierick’s 582 Long Solder Lug Terminal Connector offers a high precision connector with specifications on features such as tab size, thickness, and material plating to affect conduction and heat dissipation.

Long vs. short lugs: What’s the difference?

Although much of the emphasis for wire lugs is wire size, the length of the lug can also influence the product performance and usability.

Long solder lugs:

- Make more area for solder

- Enhanced mechanical strength and heat dissipation

- Facilitate bending or positioning the lug once installed

- Ideal for applications with vibration, thermal cycling, or frequent movement

Short solder lugs:

- Are smaller and can fit in small spaces

- Require less solder

- May be faster to install when space and time are limited

- Best for lightweight or stationary-use applications

If you’re uncertain, consider the amount of movement or stress your connection is going to get. For instance, an HVAC unit that has strong vibration may need longer lugs, whereas a small audio device might require shorter ones.

Material and plating: The often-overlooked details

Corrosion resistance, conductivity, and general reliability can be influenced by the type of material of solder lug terminals.

Common options include:

- Brass or copper for high conductivity

- Tin plated for added corrosion and solderability

- Nickel plated for higher temperature or abrasive applications

Zierick solder lug terminals, such as the 582 series, employ tin-plated brass to provide an effective balance between conductivity and an environmental barrier. If you’re working on a project for outdoor, marine, or high-humidity use, material and finish matter even more.

U.S. standards: What to watch for

For those of us here in the United States sourcing lug solder terminals, you will want to familiarize with some important standards:

- AWG sizing for matching wire gauge

- MIL-T-7928 for military-grade terminals and installation specs

- UL or CSA certifications for use in consumer or industrial applications

Compliance with these standards means your terminal is safe, working correctly, and can be used with other equipment. Anyone participating in high-spec or safety-critical product builds, be sure to check to see if your terminal needs to meet MIL or UL requirements.

Quick checklist: How to choose the right solder lug terminal connector

When in doubt, run through this list before purchasing:

- Wire gauge: Does the terminal match the AWG of your wire?

- Current rating: Can it safely carry the load without overheating?

- Lug length: Do you need long or short lugs based on the application?

- Mounting hole size: Will it fit your post or screw hardware?

- Material and plating: Is it suitable for the environment?

- Standards compliance: Does it meet AWG, UL, or MIL specs if required?

- Datasheets available: Can you verify these specs before committing to the part?

If you’re unsure, Zierick offers detailed specification sheets for each part so you can cross-reference wire size, tab dimensions, and material before you order.

Real-world example: Choosing the right terminal for an industrial switch

Let’s just say you are assembling an industrial control panel, which is a U.S. build, utilizing a toggle switch with its terminal lug solder connection. The wires are 16 AWG, and the switch will be powering around 12 amps.

You may get away with a short lug in this environment, but due to vibration and sometimes very high heat, a long lug solder terminal is just a more reliable option. You select a tin-plated brass terminal with a 0.110 tab size and a mounting hole that fits your switch’s post. The part you pick? This is Zierick’s 582 Long Solder Lug Terminal.

It’s large enough to accommodate the load, is in compliance with U.S. standards, and comes with full documentation for quality assurance.

Sourcing solder lug terminals in the U.S.

Choosing the right solder lug terminal connector is about more than just getting the cheapest option. It’s about making sure your connection is safe, strong, and built to last.

For over 100 years, Zierick has been providing high-quality terminals and interconnection systems made in the USA. Our product line includes solder terminals, press-fit options, and custom configurations that meet a wide range of industrial, consumer, and OEM applications.

If you want reliable quality, responsive customer service, and easy-to-understand spec sheets to back it all up, we’ve got you.

Explore Solder Lug Terminals at Zierick

Each and every termination makes a difference, particularly in tough applications where failure is not an option. Selecting the right solder lug terminal for the job directly contributes to your project’s success!

Explore the full line of lug solder terminals at Zierick.com, or contact us for recommendations tailored to your wire gauge, current requirements, and installation needs.

You don’t need to guess. You just need the right connection.