Faston Terminal Market Trends: What’s Driving Demand in the U.S.?

Underneath the hood of the electronics that run your house, car, or office, you’ll likely find a Faston terminal, working away without so much as a peep.

But beneath that simplicity is an increasingly competitive market. The U.S. Faston terminal market is picking up some steam due to recent innovations, automation, and increasing demand in essential end-use industries. The unassuming terminal, from the 250 Faston tabs in smart appliances to high-performance connectors in electric vehicles, has never been more important.

Here’s a look at what’s driving the growing figures, what buyers need to know, and why quality is becoming more important.

What is a Faston terminal?

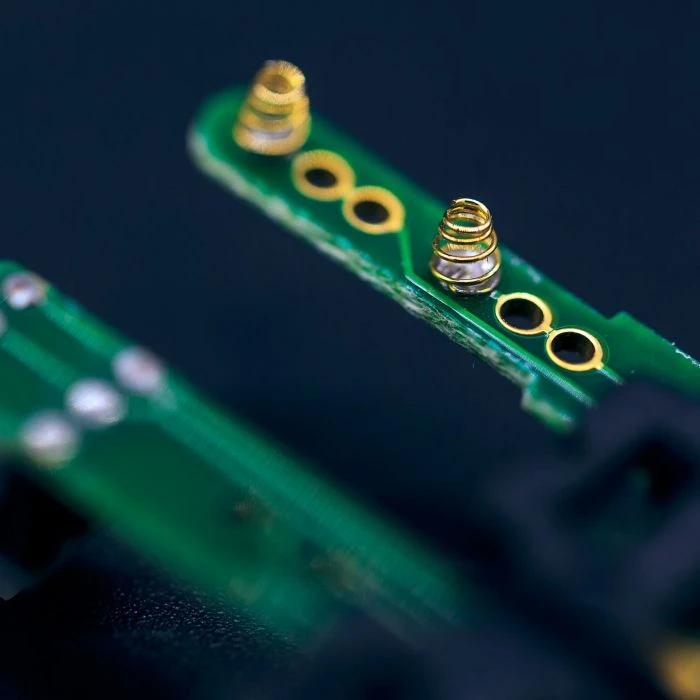

A Faston terminal, also known as a quick disconnect or tab terminal, is a type of electrical connector which is used to connect a pair of wires. They’re a popular choice in wiring harnesses when you need repeatability, speed, and reliability.

You’ll find Faston terminals in:

- Items such as ovens and refrigerators

- HVAC systems

- Industrial control panels

- Automotive wiring harnesses

- Consumer electronics

They’re made to be pushed on and pulled off without having to sacrifice electrical connection. And we’ve got standard sizes like the. 250 Faston tab, so engineers can rely on device and connector compatibility.

What’s fueling growth in the U.S. Faston terminal market?

Several industries are leaning hard into Faston technology, and it’s pushing the market upward.

1. Automotive innovation

Electric and hybrid vehicles need dependable, vibration-resistant connectors. The automotive sector generates a significant fraction of the demand for Faston-type connectors. The increasing deployment of EV infrastructure and more complex onboard electronics drives demand for more reliable heat-resistant connectors.

2. Appliance manufacturing

Appliances are getting smarter and smaller. Terminal suppliers need easy-to-install, rugged terminals that are UL-compliant. Here we have a perfect fit for the 250 Faston tab; it’s small enough to fit in the most constricted assembly, but also robust enough to ensure a strong connection.

3. Industrial automation

With robots, PLCs, and other industrial machines, fast, dependable wiring is a must. And in places where machines work around the clock, a single bad terminal can disrupt the entire operation. Which is also why we see an increasing transition to high-performance terminal solutions that save on unplanned downtime and maintenance.

4. Consumer electronics

Faston connectors are also finding their way into low-voltage, small-form-factor products. They are often used in power supplies, lighting systems, and audio equipment. And being modular makes them easy to repair, as well as permitting nimble manufacturing.

5. Sustainability and repairability trends

As consumer appetite for products that last longer and are easier to repair grows, designers are rethinking how devices are put together. Push-on terminals like Fastons support repair-friendly design, helping reduce e-waste and support sustainability efforts.

The role of the 250 Faston tab in modern design

Among the many variations, the .250-inch Faston tab has become a favorite of engineers in the U.S. Why?

It’s the best compromise of size and ability to carry current. Suitable for power and signal connections, the 250 Faston is the industry standard for the most connections to wire. It supports a wide range of wire gauges and is available in both insulated and uninsulated styles.

Some advantages include:

- No special tools required for installation

- Solid mechanical connection that will stand up to heavy use

- Compact size for space-constrained applications

- Compatibility with a variety of female receptacles

The 250 tab has been used increasingly by designers today as the complexity of circuits increases and assemblies decrease in size.

Innovations shaping the Faston terminal market

The industry isn’t standing still. While the concept of Faston terminals has stayed the same, materials, production methods, and styles have developed over the years.

Here are a few key trends:

Better heat resistance

Thanks to new alloys and coatings, it can withstand the heat of high-temperature climates. This is particularly beneficial in automotive, aerospace, and industrial HVAC systems.

Surface mount versions

SMT-compatible Faston terminals are emerging as a solution for automated PCB assembly. They are perfect for high-volume producers who require the elimination of manual insertion operations.

Custom tab designs

OEMs are looking for custom solutions that will fit particular form factors or provide the right load. It consists of angled tabs, double crimp terminals, and locking mechanisms to prevent accidental disconnects.

Sustainability-focused materials

There are manufacturers who are working to create terminals from RoHS-compliant materials and eco-friendly plating which reduces the stress on the planet.

Why quality terminals matter more than ever

Terminals are perhaps the most neglected aspect of any electrical system. But they shouldn’t be. Low-quality or poorly sized terminals can lead to overheating, poor contact, or even fire risk.

Here’s why it might pay to spend a bit more for a sturdier class of terminals:

1. Safety

A secure, consistent electrical connection prevents arcing, shorts, or other dangerous failures. This is non-negotiable in automotive or appliance applications.

2. Reliability

Your system is only as strong as its weakest link. Durable terminals reduce maintenance and repair costs over time.

3. Efficiency

Poor contact resistance can reduce current flow or create signal interference. Precision-engineered terminals maintain optimal performance under load.

4. Speed of assembly

Whether you are running a full-scale production line or assembling prototypes in a small laboratory, simple terminals can save you time and help to minimize the training requirements.

Zierick’s Faston terminals: built for performance

Zierick has been providing nearly a century of connection solutions. While our terminals are engineered for function, we also design with real-world use in mind.

Take our Faston-style .250 terminal as an example. It’s press-fit ready, RoHS compliant, and suitable for high-current applications without sacrificing simplicity. It’s designed specifically for U.S. industry standards, and is perfect for companies looking for long-term reliability without having to deal with a complicated installation.

Zierick’s connectors are used in industrial machinery, consumer devices, and smart energy systems throughout the country. With proprietary testing and support, we help sourcing teams spec and source with confidence.

Looking ahead in the Faston terminal market

As industries undergo changes and demands increase, terminals will play an indispensable role. From the basic 250 Faston tab to the most up-to-date surface mount technology, the Faston terminal industry is reacting with more intelligent, more flexible products.

This is a good time for U.S. buyers, engineers, and purchasing professionals to revisit their sourcing strategy. Working with a reliable supplier like Zierick means more than getting parts when you need them – it means getting the parts to meet spec, perform when things are happening, and grow with you.

Check Out Faston Terminals at Zierick

Check out Zierick’s complete collection of terminals and discover high-performance options that will let your team build better, faster, and safer.

Because when the connection matters, your choice of terminal makes all the difference.