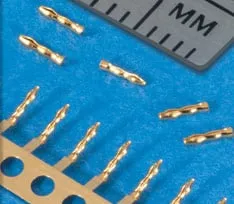

With more than 100 years of experience in precision custom stamping, Zierick offers the necessary R & D, capital intensive equipment, toolmakers, manufacturing processes, and quality control procedures to meet demanding metal stamping needs while providing savings to you. We offer premium quality stampings in medium and high volumes, in sizes up to 2 1/2″ x 2 1/2″.

Our customer-focused inventory management programs can reduce your inventory levels, while our fast turnaround helps you respond more quickly to your own customers. Leave the design, engineering, prototyping, manufacturing and quality assurance to Zierick…and make a positive impact on your bottom line.

Designing For Manufacturability

Zierick can help optimize your designs for efficient manufacturability and performance with complete design consultation and prototyping services. Using multiple Unigraphics (UG) CAD design stations with CAM capability, our key technical personnel design and implement high quality products. Located in Mount Kisco, NY, our 50,000 square foot facility includes R&D facilities; a quality assurance lab; a tool room; areas dedicated to the plating, assembly, and application equipment departments, and press room.

Our experienced engineers and die-makers provide recommendations on part and/or assembly design, tooling and die configuration, and metal stamping equipment to help achieve production economies and enhance part quality. This can often result in fewer processes performed and save thousands of dollars. We can build precision and progressive dies to accommodate even the most challenging close-tolerance requirements. Zierick can create a design, or recommend design changes to solve your end-use performance needs. In addition, our prototyping services will allow you to verify the suggested design approach.

Zierick holds many product patents, and has received numerous awards such as the Precision Metal Association (PMA) Higgins Design Award, as well as the Excellence in Design Award from DESIGN NEWS.

Progressive Die Tooling

We offer expert die tooling crafted on state-of-the-art equipment. All die sets have ball bearing pins and posts, and dies are made with guided stripper plates to provide for small sections. To ensure high speed production, lifters are incorporated into the die, while flatness correctors have been added to accommodate straight parts.

All stations are made with replaceable sections or inserts for infinite die life. In addition,Idle stations are incorporated into the design for possible future modifications.Trimming/blanking stations are made with carbide punches and bushings for low die maintenance and long life.Bend stations are multiple qualified to hold angle tolerances.Forming stations are made with sintered carbide tool steel for long life and low maintenance.Electronic Discharge Machining (EDM) is used for punches and inserts for precision accuracy and reproducibility.

Stamping: Maximizing Your Efficiencies

Our metal stamping process ensures fast turnaround and provides built-in cost saving features. For less complex components, we offer an accelerated turnkey process that lets us help you quickly and economically meet your production demands. Ask us to quote your next project!

Equipment

Zierick uses best-in-class metal stamping equipment, consisting of the following high speed presses:

- Bruderer 30-ton

- Minster 32-ton

- Minster 60-ton

Capabilities

| RoHS Compliant | |

| Material Thickness: | 0.001″ to 0.064″ |

| Size: | < 2-1/2″ |

| Square Formed Angular Tolerances: | +/- 2 degrees typical |

| Cut Angular Tolerances: | +/- 0.5 degrees |

| Manufacturing Tolerances: | +/- 0.005″ |

| Typical Materials: | C17200 Beryllium Copper |

| C26000 Brass | |

| C11000 Copper | |

| C51000 Phosphor Bronze | |

| Bronze (CDA 425000) | |

| Steel (low/high carbon and stainless) | |

| Other specialty Alloys | |

| *Slot Size less than 3 times the material thickness can add considerably to die costs. | |

In-House Plating

Our In-House barrel and strip plating lines guarantee quality and improve turn-around time.

State-of-the-Art Manufacturing

Our advanced facility houses state-of-the-art equipment and accommodates any volume. We offer multiple processes, including in-house strip line or barrel plating, trimming, blanking, bending, forming, and assembly. Whether your part designs are simple or highly complex, whether you need them flat or formed, whether you require loose parts or reel-to-reel packaging, Zierick can accommodate your application.

Zierick’s plating equipment includes:

- Small and large electroplating BARREL lines

- Reel-to-reel high speed plating line

- Cleaning, tumbling and drying equipment

- Copper

- Tin

- Gold

- Silver

- Nickel

- Lead

- Other

Zierick’s assembly process includes:

- Secondary forming operations

- Automatic screw insertion machines and tapping units for screw tapping/insertion

- US Baird® multislides

Packaging is accomplished with reel, loose piece, and tape and reel. Loose piece parts are packaged in polyethylene bags with desiccants and then heat sealed.

All parts are bar coded for accurate inventory control.

Optimizing Your Process

As an ISO 9001:2008 certified company, Zierick is committed to quality, continual improvement and customer satisfaction. We conduct verification and validation testing activities during design phases. PPAP submittal is available upon request. Production undergoes rigorous inspections to ensure precise tolerances are maintained.

Quality Inspection and Reliability Equipment includes:

- Optical Measuring vision system

- In-line vision inspection systems

- Optical comparators

- Zoom scope microscopes

- SAT steam age controller (for solderability testing)

- XRF plating thickness/composition testers

- RAM optical vision system

- Rockwell hardness tester

- Dillon tensile tester

- Force gauges

- Grinder/polisher for cross section product analysis

- Thermal shock chamber

- Electronic test equipment

All parts are bar coded for accurate inventory control.

[/vc_column_text][/vc_column]

Optimizing Your Process

As an ISO 9001:2008 certified company, Zierick is committed to quality, continual improvement and customer satisfaction. We conduct verification and validation testing activities during design phases. PPAP submittal is available upon request. Production undergoes rigorous inspections to ensure precise tolerances are maintained.

Quality Inspection and Reliability Equipment includes:

- Optical Measuring vision system

- In-line vision inspection systems

- Optical comparators

- Zoom scope microscopes

- SAT steam age controller (for solderability testing)

- XRF plating thickness/composition testers

- RAM optical vision system

- Rockwell hardness tester

- Dillon tensile tester

- Force gauges

- Grinder/polisher for cross section product analysis

- Thermal shock chamber

- Electronic test equipment