You’ve done the design. You’ve nailed the board layout. Components are ready to go.

But if the PCBoard mounting hardware doesn’t hold up, all that effort can fall apart fast.

PCB mounting hardware might not get much attention, but it’s foundational. Get it wrong, and you risk board flex, misalignment, or even electrical failure. Get it right, and your assembly holds steady under stress, heat, and time.

So what should you really look for when choosing PCB mounting hardware?

Let’s break it down.

What is PCB mounting hardware?

Think of PCB mounting hardware like the scaffolding behind the scenes.

It’s the bits that keep your printed circuit board hardware securely enclosed in the housing or system, holding everything in place, elevated and protected.

You’ll typically see:

- Spacers: To separate the mainboard PCB from the chassis or other boards

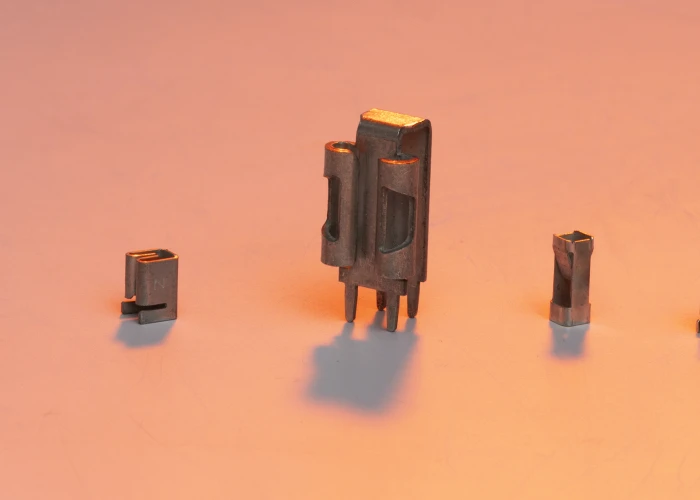

- Standoffs: Often threaded, they let you screw the board into place securely

- Clips or retainers: Snap-fit pieces to retain board without tools

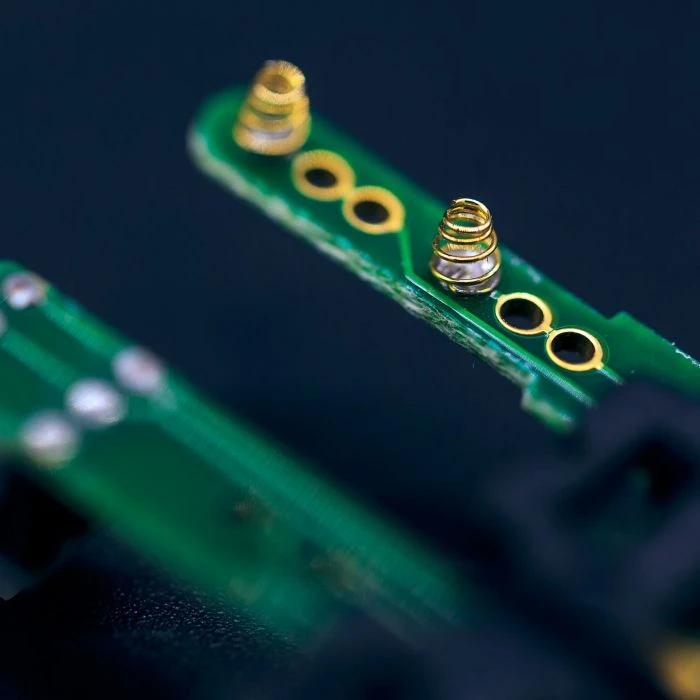

- Mounting terminals: Combine mechanical mounting and electrical connection

Each has a specific role. Which one you opt for will depend entirely on your board’s layout and intended use.

For more details, see this overview from PCBASIC.

Mounting options explained

So here’s the quick-and-easy breakdown of what you’re working with:

Spacers

Non-threaded. Used to separate the PCB board mounting surface from other components or the case itself. Great for keeping things level.

Use when:

- You don’t need to fasten anything through the spacer

- You’re trying to separate heat-sensitive areas

Standoffs

Threaded. These let you screw the board into place, which is ideal for mechanical strength and reliability.

Use when:

- Your board will experience vibration or movement

- You need easy disassembly and reassembly

- You want to stack multiple boards

Snap-fit Clips

Tool-free. These hold the PCB in place with pressure and are useful in lightweight or temporary setups.

Use when:

- You’re working with lightweight assemblies

- Quick install/removal is key

- Space is tight, and screws would interfere

PCB Mounting Terminals

Now we’re talking hybrid hardware—pieces that mount the board and serve as pc board terminals for electrical connection. Think: efficient and compact.

Use when:

- You want to save space

- You’re managing high-current connections

- Durability and reliability are essential

You can explore Zierick’s mounting hardware here. Tons of options for a variety of board layouts.

How to choose the right PCB mounting hardware

It’s not just about the hardware type. It’s about the material and placement of your PCBoard mounting hardware.

Here’s what to consider when selecting the right mounting solution:

Board size

Bigger boards? More support. You’ll want more standoffs or heavier-duty spacers.

Smaller boards? You might get away with just two mounts, but only if the board isn’t flexing under pressure.

Vibration and movement

Industrial control units. Automotive sensors. Robotics. If your application moves, the mounting has to lock in tight.

Threaded standoffs are your best friend here.

Material

Metal = strength.

Plastic = lightweight and non-conductive.

Each has pros and cons. Metal is durable and heat-resistant, but can trigger ground loops if not isolated. Plastic is nonconductive, making it safe for sensitive circuits, but may become brittle after repeated flexing.

Use plastic where insulation matters.

Use metal where heat, strength, or tight tolerances are in play.

Clearance

You’ve got to plan for heat dissipation and airflow. Your PCB mounting hardware shouldn’t block that.

Standoffs or spacers that are too short? That’s a recipe for heat damage or signal interference.

More guidance on these design choices is available in this FlyWing-Tech breakdown.

PCB board mounting: what people get wrong

Here’s where many builds go wrong:

- Mounts too close to sensitive traces

This one’s brutal. If your screw head hits a trace, you’re asking for interference or even a short. Always plan spacing around your mounting points. - Wrong materials for the environment

Plastic standoffs used in a high-heat enclosure? Cracked and melted in a week. Metal spacers in a consumer electronics device that needed full insulation? Hello, unintentional ground loop. - Not enough support

Boards with only two mounting points (when they really needed four)? Sagging. Warping. Early failure.

Real-world mounting scenarios

Want to see where this all comes into play? Here are a few real-world examples where choosing the right printed circuit board (PCB) hardware can make or break the design:

- Automotive control modules: High vibration and temperature. Threaded metal standoffs with insulation are standard.

- Consumer routers or IoT devices: Low stress. Plastic spacers or clips can work well here.

- Industrial sensors: Exposed to impact and dust. Sealed mounting terminals and robust standoffs are critical.

- LED driver boards: Heat management is key. Choose standoffs that induce no thermal stress and provide air circulation.

Each use case will have its specific needs, but in all cases, the intention will be the same: to help, shield, and preserve your board’s function.

FAQs

Q: Can I use plastic standoffs in a power supply board?

A: You can, but it’s risky. Power supplies get hot. Better to go with heat-resistant material like nylon 6/6 or metal with an insulating washer.

Q: How do I prevent board flex during mounting?

A: Add more support points. At least four for larger boards. And make sure the mounting holes are aligned—no forcing or bending.

Q: Is tool-free mounting reliable long term?

A: For static environments, yes. For mobile, vibrating, or industrial use? Probably not. Go with something screw-secured

Why PCB mounting hardware matters (and why Zierick’s a smart choice)

At the end of the day, PCB mounting hardware is a foundational part of your board design. It doesn’t get the spotlight, but it holds everything else up.

Zierick offers a range of printed circuit board hardware options that are tested for durability, stress tolerance, and ease of install. So you’re not just securing a board, you’re building a system that’s designed to last.

And with Zierick’s high-quality pc board terminals and socket connector pins, you can mount, connect, and trust the performance all in one move.

Explore our full printed circuit board (PCB) hardware lineup here.

The right mount makes all the difference. And Zierick’s got the goods.