|

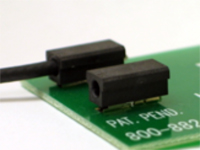

Zierick offers its newest insulation piercing connector for Coaxial Cable — the IPC-2-1-T Connector. This connector offers a cost-efficient, reliable solution for RG174/U or RG316/U coaxial cable terminations. By allowing reliable one-step termination of the shield and conductor within a plastic housing, the connector reduces assembly costs associated with soldering and provides a more durable wire connection.

Design

Zierick’s IPC-2-1-T Connector design builds on Insulation Piercing Connector (IPC) technology, which is the ideal method for wire termination. IPC technology allows multiple wires to be terminated simultaneously by removing the outer jacket and stripping the braid.

This connector features a unique design of a tapered wire housing hole and three individual piercing blades that terminate both the shield and conductor. The piercing blades are made to go in one direction only, and maintain a continuous force on each wire. Its durable plastic housing provides excellent wire retention.

Process

First, these IPC connectors are surface mounted to the PCB. After reflow, the outer jacket is removed and the braid is stripped before the cable is inserted into the hole of the housing. Force is then applied to the top of the plastic housing and the piercing blades cut through the insulation and penetrate into the shield and the cable’s core—completing the wire connection process.

Benefits

Zierick’s IPC-2-1-T Surface Mount Coaxial Cable Connector:

Saves you labor time and costs.

- Eliminates the need to solder wires to the PCB

- Allows for the efficient termination of both the shield and conductor at the same time

Gives you a higher quality termination.

- Maintains consistent pressure on the wires for better conductor contact

- Provides superior retention to the board

Provides a more cost-efficient solution.

- Uses minimal PCB real estate

- Offers the least expensive method for wire termination

|

Surface Mount

Surface Mount